12 Best Packaging Machines Revolutionizing The Industry To Streamline Your Production

Improving your packaging process is essential to make your production faster and smoother. From a list of advanced machinery featured with the latest technologies, it is challenging to decide which type of packaging machinery is the right fit. What type of machine you should go with makes you confused? Fret not.

Stay ahead with the latest and top packaging machines this year to maximize your production line. This ultimate guide covers key factors, tips, and the latest advancements in packaging technology.

You will learn about essential features and innovations to boost efficiency, optimize your packaging process, and enhance your business functions. It will help you choose the right packaging machine to streamline operations that are fit to cater to your business needs.

What is A Packaging Machine

Packaging machinery aims to produce packaging for various products, ensuring the packaging for that particular product is manufactured in the exact dimensions, shape, style, and visually appealing to fulfill the requirements.

These specialized types of machines for packaging are vital for various businesses and industries that look to accommodate their products in boxes and bags to serve their customers better. Some of the most popular industries and sectors that require packaging are:

- Automotive

- Electronics

- CBD

- E-commerce

- Cosmetics

- Fashion

- Sports

- Pharmaceuticals

- Food, and beverages

- Many more

The latest development in this modern age is using an automated system in a packaging machine. This innovation has made operations faster, smoother, and easier by putting little labor effort into running technical operations.

Not just that. It has also reduced labor and enhanced the output to boost production in less time. You don’t need many workers except the ones to run a packaging machine accordingly.

1. Stick Pack Packaging Machines

Stick pack packaging machine refers to creating stick packs sachet, or tube-like packaging to serve single dose products.

This food packaging machinery works efficiently at high speed with minimal waste. It is designed with sanitary features to maintain product purity.

This machine can be suitable for fine powder and grain products such as coffee powder and milk powder.

Apart from that, this machine can help you pack spice powder, sugar, salt, or pharmaceuticals.

2. Cartoners

The cartoner is an automatic packaging machine that forms, fills, and seals cartons without any hassle.

These food packaging machines for small businesses are ideal for packing liquid or semi-liquid items.

You can find these cartoner machines in various sizes and styles. It can help you fill and seal food, pharmaceutical, cosmetic items, and consumer goods in a carton box.

3. Flow Wrapping

This flow wrapping machine is fast and efficient for continuously wrapping around the product with a plastic film. It creates a pillow and a heat-sealing lock in the air.

If you want your candies and snacks to be wrapped fast, you must consider this speedy machine.

4. Shrink Wrapping

This wrapping machine is used to wrap products with a plastic film. The plastic film shrinks when it is heated which results in producing a tamper-evident and protective seal

If you want to shrink wrapping for water bottles or cosmetic products, this machine is ideal for bundling multiple products.

5. Pre-Made Pouch Bagging Machines

These pre-made pouch bagging machines are designed to fill and seal existing pouches using a zipper or non-zipper system.

This machine loads pouches delivers the products into the pouch and closes it with a secure and airtight seal.

The automated process of this machine is good for faster production. Plus, this machine reduces labor costs while offering versatility to handle various pouch sizes and product types.

The use of this machine is at a larger scale in industries like food, pharmaceuticals, and agriculture.

6. Vertical Form, Fill, and Seal (VFFS)

VFFS machines create pouches and bags from a roll of film and seal them after filling the products. Usually, these machines are used to pack snacks, grains, and powders.

This machine operates at high speed to handle various packaging materials. Further, it is adaptable to different types of products. However, if you want to pack large or fragile items, this machine would not help.

7. Horizontal Form, Fill, and Seal (HFFS)

HFFS machines are similar to VFFS but operate horizontally to create, fill, and seal packages from one roll of packaging material.

They are suitable for products that require horizontal packaging like baked goods and ready meals.

The best thing about this machine is offering flexibility, high-speed packaging, and reduces material waste. However, this machine may be not effective for irregular or vertical-shaped products.

8. Thermoformer

A Thermoforming machine is a large manufacturing equipment that takes a plastic sheet and molds it to create a container in a custom shape and size.

A Thermoforming machine is a large manufacturing equipment that takes a plastic sheet and molds it to create a container in a custom shape and size.

It transforms a flat plastic sheet into three dimensional object which is why it is considered effective in creating a wide range of plastic products.

Furthermore, it is suitable for storing medical devices, automotive, and food items.

9. Palletizers

Palletizers are machines to automate the process of stacking products onto pallets for storage and transportation.

This food packaging equipment is commonly used in industries such as pharmaceuticals, food and beverages. It improves efficiency and accuracy in the whole packaging process which cuts down labor expense.

These machines enhance productivity, reduce the risk of injury, and handle various packaging sizes along with their weight.

10. Tray Sealers

Tray sealers are machines to package products in a tray and seal them with a plastic or polystyrene tray lid or film.

This machine produces protective, airtight, and more effective trays to protect products and prevent external contamination.

Using this packing machine for food products, you can preserve meat, fish, and pharmaceutical items to preserve their quality.

11. Blister Packaging Machines

Blister packaging machines - also known as blister packs are specialized machinery. They are used to package tiny items like pills in a protective plastic shell.

These blister packs consist of a plastic cavity that is sealed with a backing material of aluminum foil to create tamper-evident and secure packaging.

12. Labeling Machines

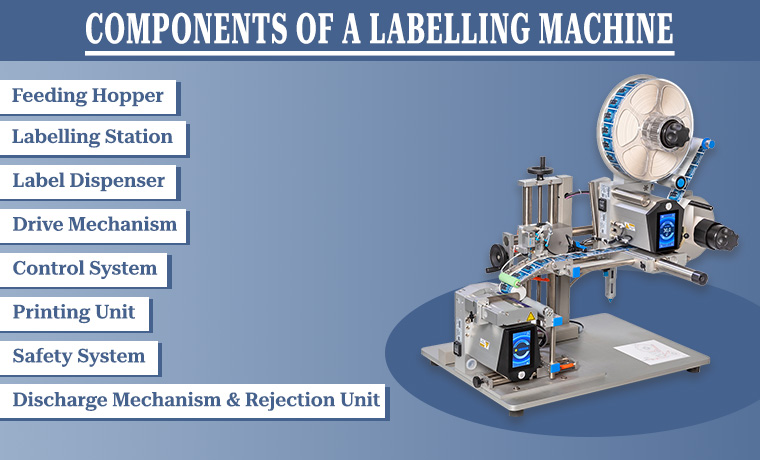

Labeling machines are specifically designed to efficiently apply labels to products, packages, and containers at high speeds. These advanced machines ensure accurate and consistent labeling.

They can handle various product labels of different materials such as pressure-sensitive labels, shrink sleeves, wet glue labels, and hot melt labels. Many types of automatic sticker labeling machines are found to serve many industries.

Food, pharmaceuticals, and cosmetic labeling machines are some of the examples before us to help you experience this machine for effective results.

Conclusion

Automatic packaging machines are fundamental as product packaging is crucial for a business to streamline whole operations, minimize labor expenses, and produce packaging in the exact shape and size you need. In the range of most advanced packaging machinery, it is pivotal to know the essential features of each machine type and its perks to help you judge what type of machine is completely matchable for your business needs.

If you are hunting for a trustworthy and reliable packaging manufacturer, stop looking here and here. Custom Product Packaging is equipped with the most advanced and state-of-the-art machinery to bring your packaging vision to the paper. Feel free to contact our packaging specialists by emailing us at orders@customproductpackaging.com for technical guidance and support.