A Comprehensive Guide To Soft Touch Coating: Benefits and Applications

Would you like your customers to enjoy a pleasant tactile experience when they touch your packaging box paper? If so, consider using a soft touch coating. This special type of coating provides a velvety, soft touch, matte finish, and a unique feel when applied to the surface of materials. When used during the printing process, it dries quickly and can be a valuable asset for your business, leaving a lasting impression on customers.

The paper becomes soft when this coating is applied. Most often, this soft touch coating printing is used for luxury products to give them a sophisticated and premium look. Featuring fingerprint and moisture resistance, this type of coating is ideal. The best thing about soft touch coating is protecting the paper sheet from scratches marks, and scuffs such as binding, folding, or cutting during the finishing operation.

Creating a velvety, soft, and luxurious feel for the svelte presentation of your products can benefit printing almost any kind of packaging. From smooth business cards, luxurious brochures, and soft postcards to catalogs, it is considered the most suitable coating. Hold your horses to learn about this coating through this definitive guide. So, let’s get started.

What Is Soft Touch Coating

Soft touch coating is a finishing technique applied in liquid form on the surface of materials like cardboard, paperboard, or plastic during the printing process to create a velvety appearance This finishing is known for its versatility and fast drying feature.

Soft touch coating is a finishing applied to surfaces, commonly on printed materials to achieve a velvety, smooth, and tactile feel. It enhances the sensory experience by offering a soft and luxurious texture.

This coating enhances the aesthetic appeal of items and durability by offering protection against scratches and fingerprints. Soft touch coatings can vary in composition but commonly involve specialized polymers that create the desired tactile effect without compromising functionality or visual appeal.

Enhanced Feel and Aesthetics With Soft Touch Coating Printing

Soft touch coating gives a premium and luxurious feel to the surface of the printed items where this finish is applied. It enhances the overall appearance of the product packaging and the materials. When the products are displayed in a box printed with this soft touch paint, it gives a more valuable look that is hard to neglect the package. Therefore, it shines customers' eyeballs and grabs their attention.

Improved Durability Of Soft Touch Coating Offers Protection

As a water-based coating, it is environmentally friendly and reduces waste. Wear and tear are not a problem because this coating protects against scratches. Water, fingerprints, and moisture cannot penetrate its surface, thanks to its durability. The soft and rubbery texture of the coating improves grip on products like handheld devices, tools, and electronics, making them more comfortable to hold.

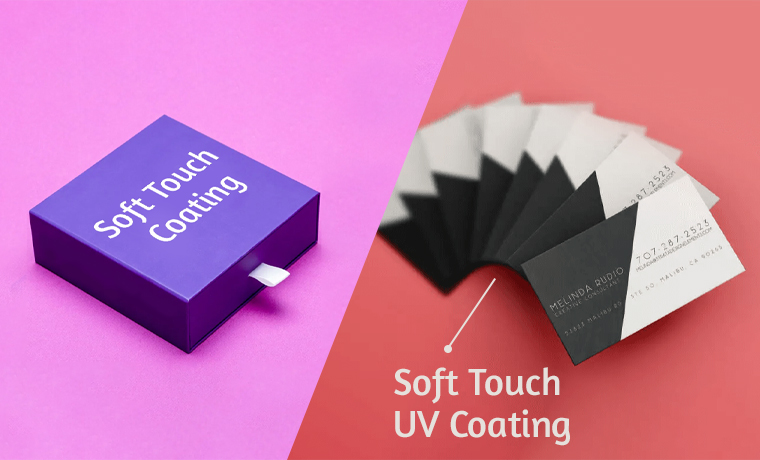

How Soft Touch Coating Differs From Soft Touch UV Coating

The surfaces of printed materials can be enhanced with a soft, smooth, and velvety texture using soft touch coatings and soft touch UV coatings. These coatings vary in terms of application and durability. Water-based soft touch coating is applied to printed items using rollers and sprayers. It creates a matte or satin finish and provides moderate scratch resistance.

While soft touch UV coating involves applying UV-curable formulation with UV light that results in a hardened finish. It contains VOCs (Volatile organic compounds) that are suitable for applying on the materials to enhance their durability. Besides this, it offers superior durability and resistance against scratches.

|

Features |

Soft Touch Coating |

Soft Touch UV Coating |

|

Application Method |

Applied as a liquid coating and cured through evaporation or heat. |

Applied as a UV-curable liquid coating and cured instantly using UV light. |

|

Texture |

Smooth and velvety feel with a matte appearance. |

Smooth and velvety feel with a matte appearance. |

|

Durability |

Moderate scratch resistance. |

Improved scratch and abrasion resistance compared to standard soft touch coatings. |

|

Appearance |

Enhances color richness and depth. |

Enhances color richness and depth. |

|

Environmental Impact |

Typically solvent-based, but water-based options are available. |

Generally considered more eco-friendly due to lower VOC emissions and faster curing process. |

|

Cost |

Moderate cost. |

Slightly higher cost due to UV curing equipment and materials. |

Versatile Soft Touch Coating For Plastic

Soft touch plastic coatings are versatile for a variety of industries since they combine tactile and aesthetic appeal. In addition to electronics, automotive interiors, packaging, household appliances, medical devices, toys, and games, this coating offers customizable options for color and texture.

Besides this, this soft touch coating printing offers an enhanced grip on the products, scratch resistance, prime appearance, and feel. From user comfort, pleasant touch, and reduced fingerprints to usability and aesthetics, this coating is an excellent choice for various industries mentioned above.

How To Remove Soft Touch Coating

Removing soft touch coating is a challenging task. The reason is that it adheres to the surface of the printed materials However, it depends upon the type of coating, substrate material, and the level of adhesion. You can try to remove it by applying different techniques. Should we discuss them?

Isopropyl Alcohol (IPA):

It can soften and dissolve soft touch coatings. Try to use a piece of cloth soaked in IPA and gently rub the coated surface. Rub it carefully to avoid any damage to the material.

Acetone:

A more potent solvent capable of breaking down certain types of coatings. Ensure the substrate does not change color before applying it to a larger area. Gently rub the coating with a cotton swab or cloth until it starts to lift.

Heat Gun:

It removes the coating with a heat gun set at a low temperature. Excessive heat applied to the material can ruin its quality.

Mechanical Abrasion:

Use a gentle mechanical abrasion with fine-grit sandpaper if the coating is stubborn. This method should be carefully applied to avoid any scratching to the substrate.

Paint Strippers:

The paint strippers - adhesive removers are effective against soft touch coatings. You need to follow the instructions given by the manufacturer and test on a small surface.

Final Thoughts

To conclude this guide, solvent-based formulation soft touch coating meets specific aesthetic and functional requirements while offering a tactile feel with a smooth, velvety texture and resistance against scratches.

At Custom Product Packaging, our packaging experts deeply understand the significance of this coating and assist our clients with expert-level guidance. For your assistance, we are available. To learn more or want to book an order, email us at orders@customproductpackaging.com. We will be pleased to serve you better than others.

Also Read: Understanding Of Soft Touch Lamination