Essential Types of Foam Packaging You Should Consider In Transit

In an expeditious world of shipping and logistics, where billions of products are shipped daily, the safety of products is essential during handling and transit. To counter this issue, the role of foam packaging offering a cushioning barrier against wild vibrations, jolts, shocks, and temperature fluctuation is vital. Your product packaging becomes special when you ship products with protection using soft packing foam to make customers feel happy when receiving their products in genuine condition.

Foam packaging—a type of polyurethane foam is essential to packaging, offering safety and security to the products or goods you transport during transit. Many removal companies often use this foam sheet when moving to pack goods or delicate items within the box. Shoes wrapped with this foam are positioned in a box to ensure safety. Another example is a TV that is likely placed in a box with a flexible foam sheet for protection.

So, shipping foam is an excellent choice to avoid physical damage and environmental elements hitting your fragile and heavy-duty items. However, foam packaging has various types that will be discussed. Wait here. This guide will explain the types, materials, and benefits you may need to know. So, let's make a start.

What is Foam Packaging? Why Should You Need It

Foam packaging is a thin, clean, and protective material made from foam. It comes in different forms: sheets, thin foam rolls, peanuts, charcoal pick and pull grid foam, pre-cut shapes, packing foam blocks, pouches, and inserts. This lightweight shipping foam packaging offers excellent cushioning, shock absorption, and insulation properties to protect products in transit. With these soft yet protective foam sheets for packing, you can store and protect your fragile items.

Unlike newspaper wrapping glassware, this soft packing foam contains thickness and diversity and is ideal for safeguarding various products. It is a versatile and cost-efficient choice that can act as a barrier to protect your fragile electronics, pieces of equipment, and other delicate goods.

Paramount Types of Foam Packaging With Their Applications

There are many foam types for packaging available. Most of them are made from polyurethane, polyethylene materials and have distinct applications. Foam sheets, tubing, wrapping, chips, corner protectors, inserts, trays and sleeves are popular. Wait, a lot more types are discovered.

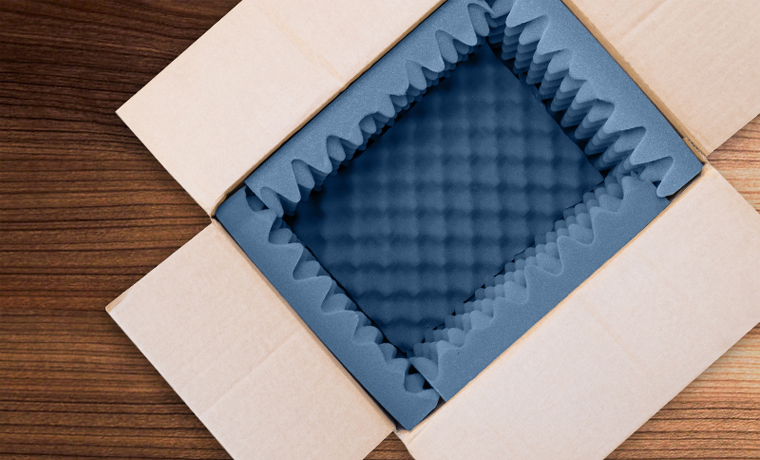

Egg crate foam padding in sheet form is available, which is suitable for keeping items in place and restricting their movement during storage and shipping. Another shielding foam packaging type is closed-cell polyethylene foams with closed-cell polyethylene structures, which are lightweight, versatile, and durable enough to resist water, moisture, heat, oil-based substances, and chemicals and absorb shocks.

EVA foam—a durable, flexible, and pliable foam packaging type—is a closed-cell foam made from ethylene-vinyl acetate known for its soft, rubbery feel, durability, and water resistance. It suits sports, cosplay, pop-making, home decor, mat-making, and DIY projects. Cutting it into the required shape and size is easy with scissors or knives. This lightweight, soft packing foam is water-proof and ideal for outdoor applications.

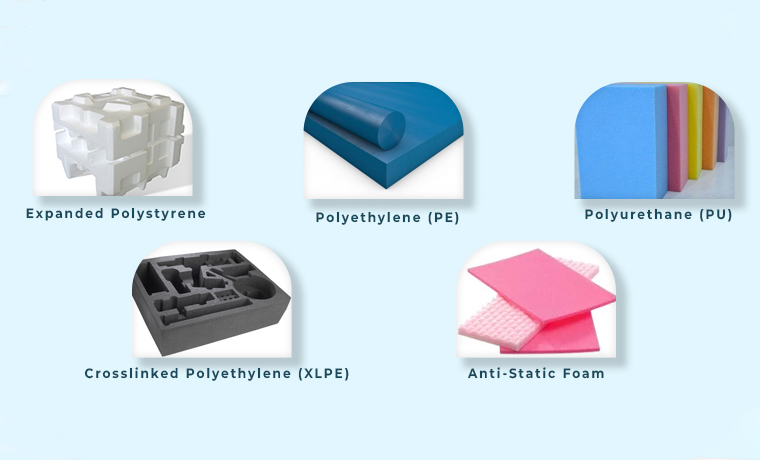

Types of Foam Packaging Materials

Foam packaging is vital to keep your breakable and vulnerable products during storage and shipping. When learning about its material types, they are distinct in their features and properties.

1. Expanded Polystyrene (EPS):

Known as Styrofoam, a lightweight, rigid, least expensive, water and shock-absorbent. It comes in foam blocks, produced from solid polystyrene beads, and is a good choice for guarding various items like electronics and appliances.

2. Polyethylene (PE):

Highly durable closed-cell foam offers exceptional water, chemicals, and mold resistance. It material safeguards heavy machinery parts, robust cables, and delicate pharmaceutical products from damage caused by moisture and harsh environmental conditions.

3. Polyurethane (PU):

Soft and flexible open-cell foam comes in various colors and shapes. It excels at carrying weights, cushioning fragile items, and safeguarding products from minor scratches. For delicate items such as TVs, refrigerators, laptops, car bodies, and sensitive items, this is a reasonable choice.

4. Cross-Linked Polyethylene (XLPE):

It offers superior shock and water absorption. Stiffer and more expensive than polyethylene but suitable to protect high-end and valuable products such as military and pharmaceutical equipment.

Styrofoam For Packaging - A Protective and Defensive Shield To Safeguard Your Products

Styrofoam is a replacement for polystyrene. It is a lightweight and rigid plastic material famous for its outstanding protective properties, including shock absorption. Its classic sponge structure, full of tiny holes, is perfect for absorbing shocks and vibration and protects delicate items during transportation.

It also includes excellent thermal insulation to keep products under complete temperature control in case of temperature fluctuations. It's lightweight, which makes it easy to fold and mold in any shape to fit products and reduce shipping costs. You can easily handle and carry it without any frustration. This Styrofoam is suitable for businesses that require lightweight and affordable foam packaging solutions.

Making The Right Selection Of Foam Packaging

When it comes to shipping your valuable items in a packaging box, it is essential to determine the weight and size of the product. It can help you choose a foam packaging material containing stiffness and durability to bear the weight of the product in transit.

For spoilable products, you must consider a shipping foam to protect them from heat and moisture that can even extend their retail shelf life. If you are shipping items containing fragile surfaces, opt for a lid made from polyethylene (PE), offering stiffness and protection to the products.

So, from foam wrap packaging to thin foam roll, you have got plentiful options. It depends on the product packaging requirement which is ready to transit.

Let’s Wrap Up The Things

Foam packaging is crucial to meeting your logistics challenge. You will agree that it can secure your heat-sensitive products or delicate items during shipping and handling. Each type of foam and material, from polystyrene to crosslinked polyethylene, contains fantastic benefits you will surely want to use to ensure the safe delivery of each product.

We, Custom Product Packaging, take care of every packaging order with a commitment to excellence. Choosing us means partnering with a leading custom packaging manufacturing company and having a team of packaging specialists offering quality packaging at an affordable cost. Please send us your requirements at orders@customproductpackaging.com and begin a journey of matchless packaging innovations with us. Get in touch with us TODAY!